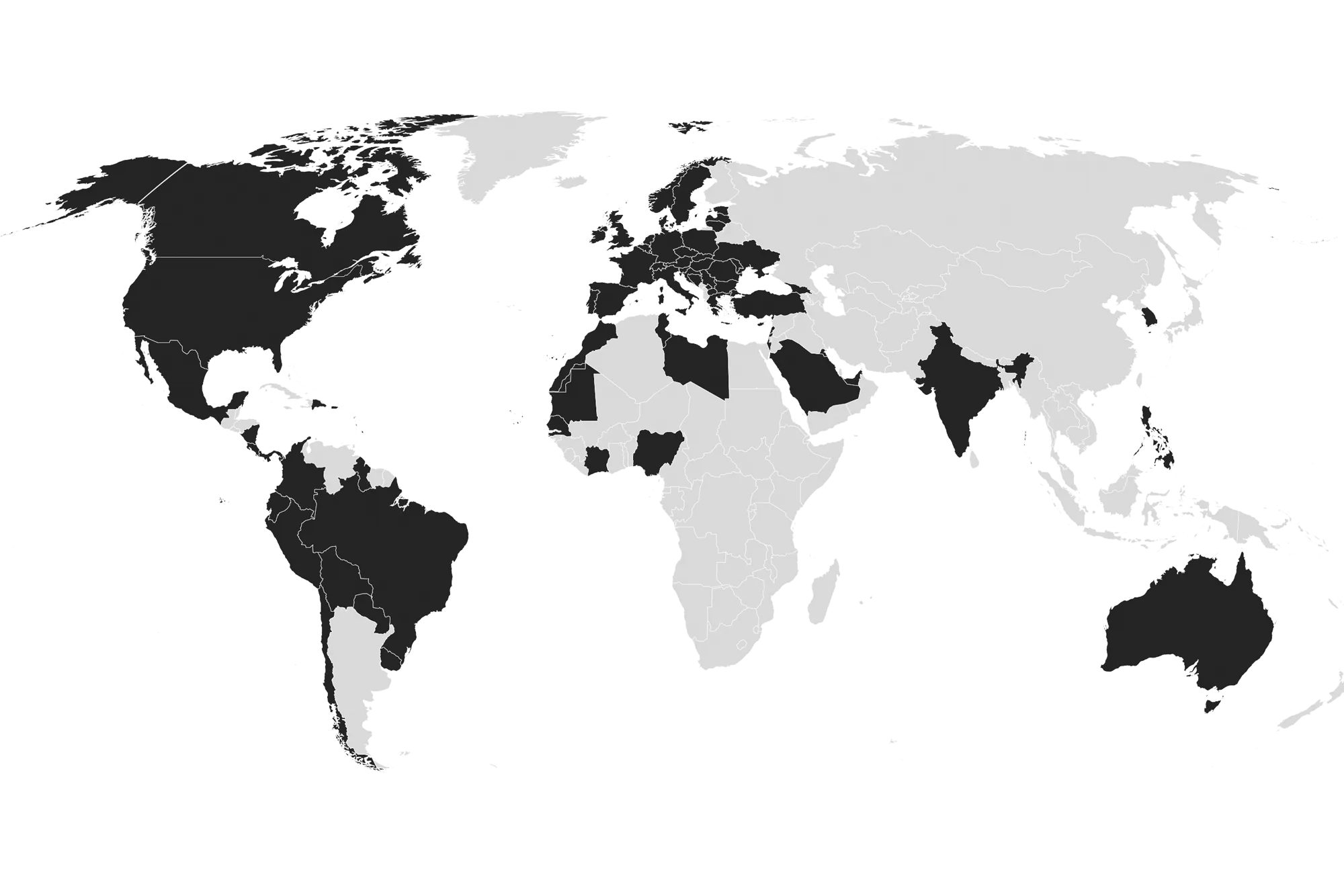

CORTIZO Bulgaria is a leading manufacturer of aluminum and PVC solutions for architecture and industry. Innovation and integration of the entire production process are the key to our business model. This allows us to develop high added value products that we offer to the market in 87 countries on 5 continents.

We have 9 factories in Spain, France, Poland and Slovakia. They have an annual production capacity of 150,000 tons of aluminum profiles and 50,000 tons of PVC. In addition, our extensive logistics network is made up of 31 distribution centers and 4 local technical offices. This allows us to offer immediate and close customer service.

Behind these impressive numbers is the talent of our team, which currently consists of nearly 4,000 people. This is essential for the development and expansion of the company.

We are a family company with a global vision that aligns its activities with the Sustainable Development Goals. We are also committed to growth that has a positive impact on the environment. We also promote the economic and social development of the regions in which we operate.

We develop customized aluminum solutions for a wide range of industrial sectors. We add value to the extrusion of profiles that are transformed into ready-to-use components.

Thanks to its excellent properties, aluminum has become an indispensable ally in countless applications. In the transport sector, for example, it allows the creation of lightweight and durable structures that significantly reduce fuel consumption. Our Rail and Marine Engineering department works hand in hand with key players in the sector, designing specific profiles for this area.

Beyond transport, aluminum is essential for the production of all kinds of products:

Our commitment to innovation has allowed us to develop a catalog of more than 80 <strong>aluminum and PVC systems</strong>. Because they are adapted to the construction realities and regulatory requirements of each of the countries in which we operate.

Behind Cortizo windows, doors, facades, railings and sun protection solutions is the continuous work and close collaboration of a multidisciplinary team. This team is led by the Research, Development and Innovation (R&D&I) department. They all shape market trends and respond to emerging needs, designing all the profiles, seals and accessories that make up each fence.

After successfully completing laboratory tests, we manufacture all the components in our own production facilities. The exception is glass. We supply the materials to our customers, who are responsible for the manufacture and installation of the fences under our brand.

We also have the ability to design individual facade envelopes for skyscrapers and highly complex architectural projects around the world. This is made possible by our Large Project Engineering department. It specializes in designing unique facades incorporated into iconic buildings on all five continents.

Our commitment to innovation has enabled us to develop a catalog of more than 80 aluminum and PVC systems adapted to the construction realities and regulatory requirements of each of the countries in which we operate.

Behind Cortizo’s windows, doors, facades, railings, and sun protection solutions lies the continuous work and close collaboration of a multidisciplinary team led by the Research, Development, and Innovation (R&D&I) department. They shape market trends and respond to emerging needs by designing all the profiles, seals, and accessories that make up each enclosure. After successfully completing laboratory tests, we manufacture all components—except for the glass—at our own production facilities and deliver the materials to our customers, who are responsible for manufacturing and installing the railings under our brand.

In addition to offering an extensive product catalog, we have the ability to design custom facade cladding for skyscrapers and highly complex architectural projects around the world. This is possible thanks to our Large-Scale Projects Engineering department, which specializes in designing unique facades for iconic buildings on all five continents.

✔️ Integrated process: from casting and extrusion to anodizing, powder coating, and recycling

✔️ Factories: 11 production centers in Europe (Spain, France, Poland, Portugal, etc.)

✔️ Technologies: automated extrusion lines, in-house testing laboratories

✔️ Sustainability: 100% recyclable aluminum, reduction of carbon footprint through green energy

✔️ Network: over 31 distribution centers in Europe

✔️ Logistics: fast deliveries, integrated warehouse systems

✔️ Support: technical teams ready to assist architects, engineers, and partners

✔️ Local presence: distribution network in Bulgaria and the region

Together with Mig Market, we offer

expanded opportunities for our customers.

You can edit quantities or remove items before emailing your request.